|

|

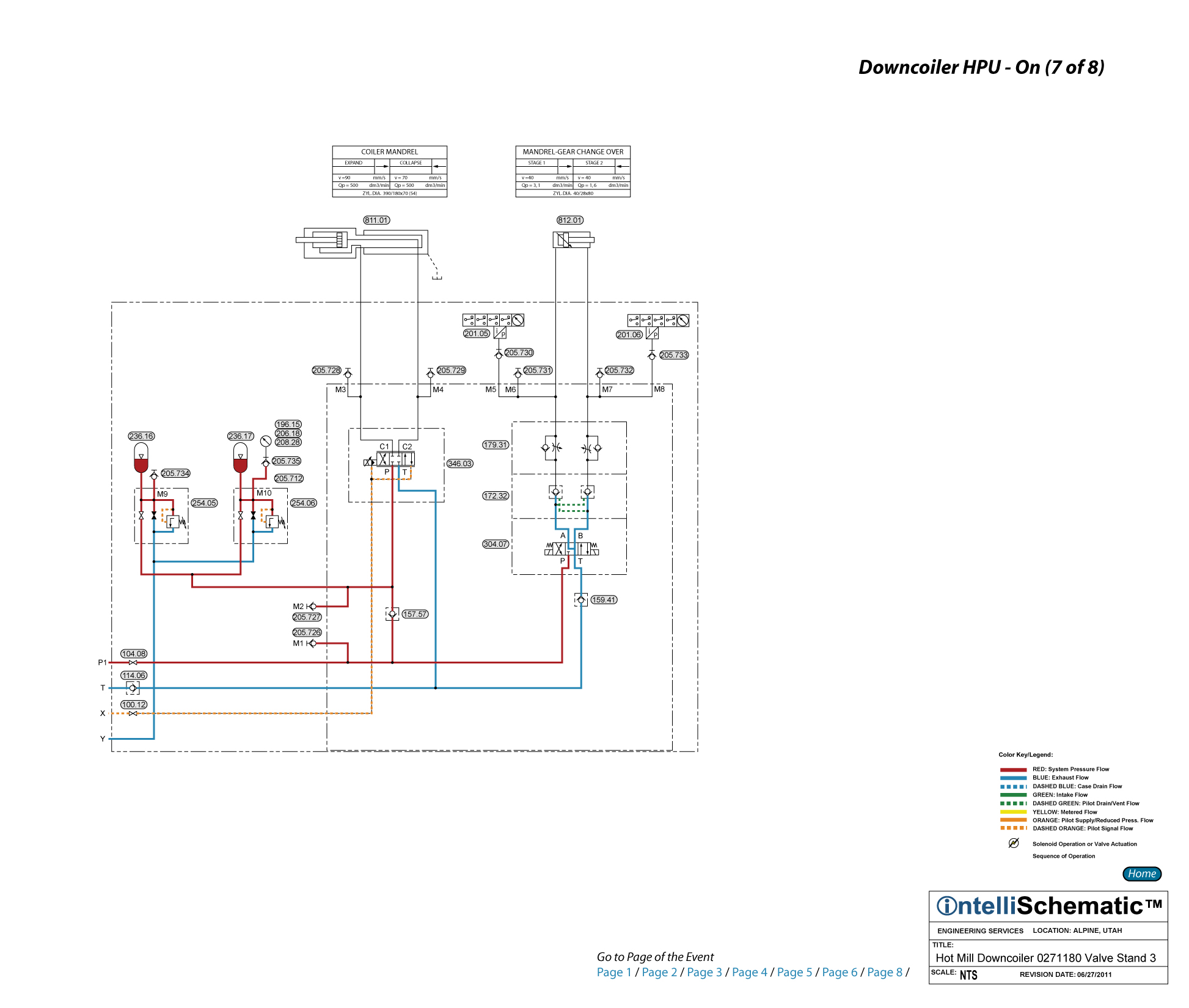

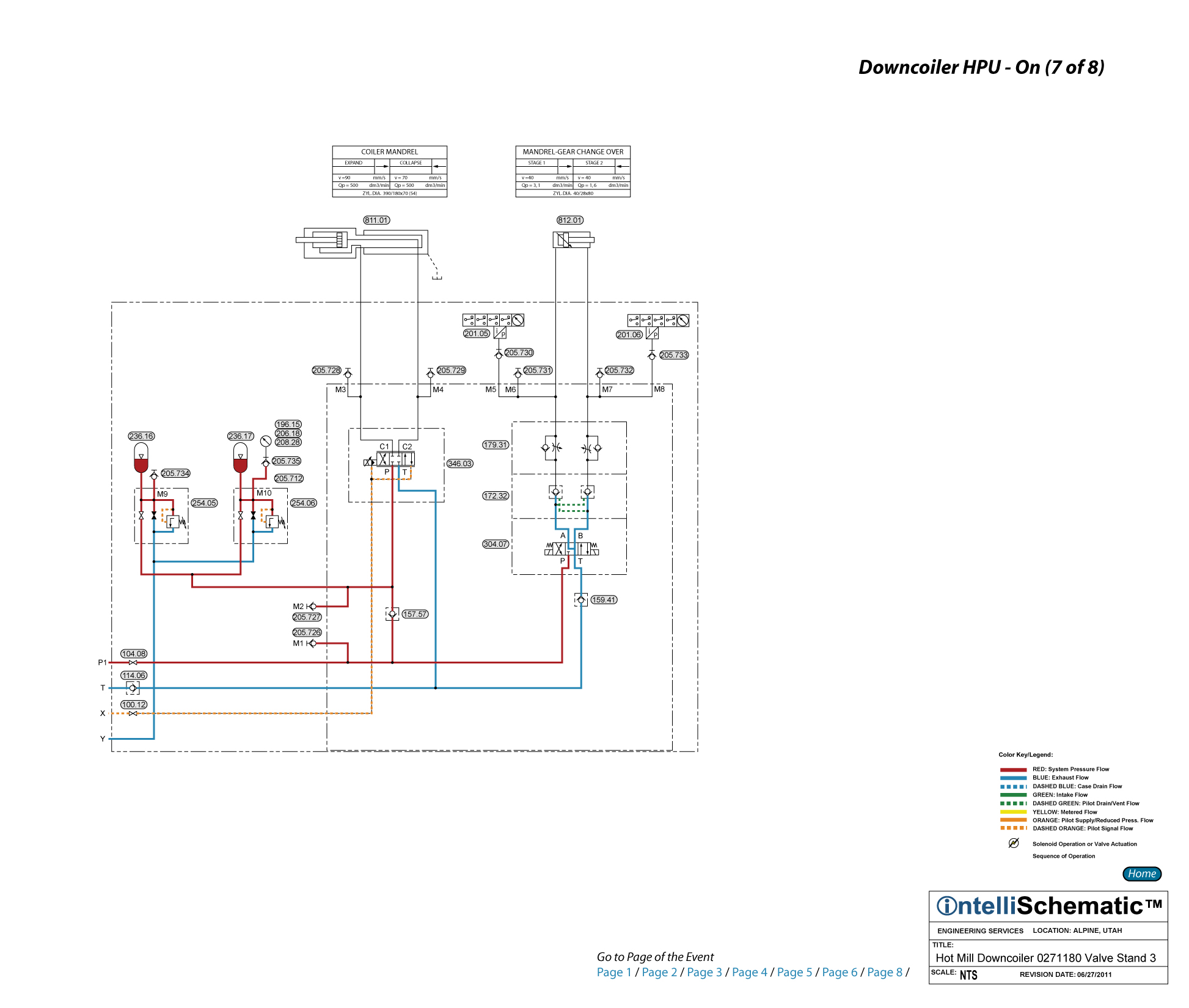

Downcoiler HPU - On |

The Low Pressure Pump Group and Pressure Header Line P1:

The low pressure pump group consists of five pressure compensated piston pumps, 003.01 through 003.05, powered by Electric Motors 820.01 through 820.05, respectively. During operation of the Coiler, only four pumps operate. The fifth pump is an installed standby.

The pumps draw freely from the reservoir through Butterfly Valves 072.01 through 072.05, respectively. The flow delivered by each pump flows through a pressure line filter (052.03 through 052.07, respectively). The filtered hydraulic fluid then flows through a check valve (157.38, 157.40, 157.42, 157.44 and 157.46, respectively) into a common pressure header line which supplies a manifold which includes Solenoid Vented Relief Valve 261.02. Though this relief valve may be vented to low pressure, in practice, this valve is always energized to high pressure, even when the low pressure pumps and motors are not operating. In addition, each pump is protected from overpressure by its own pressure relief valve (285.03 through 285.07, respectively). Any vented flow from Relief Valves 285.03 through 285.07 flows into a common return header line; backflow from that line to these relief valves is prevented by Check Valves 157.37, 157.39, 157.41, 157.43 and 157.45, respectively. The case drain flow from pumps 003.01 through 003.05 flows back to tank via a common return line. Backflow to the case drain port of these five pumps is prevented by Check Valves 143.08 through 143.12, respectively.

Also included on the manifold discussed above are two DIN Cartridge Valve Assemblies (363.01 + 364.01 + 388.02 and 363.02 + 364.02 + 363.03) which are plumbed in parallel with Flow Control Valves 168.01 and 168.02 and Check Valves 158.10 and 158.11. One set of valves controls the flow delivered to the P1 circuits on Coiler 1 and the other set of valves controls the flow delivered to the P1 circuits on Coiler 2. When the DIN Cartridge Valve Assemblies are energized pressurized hydraulic fluid may bypass unrestricted around the respective flow control valve.

This manifold also supplies fluid to the Laminar Cooling Circuit, the Pilot Pressure Stand, which consists of Pressure Reducing Valve 287.03, Accumulator 235.15, Accumulator Safety Valve 254.04 and Pressure Switch 202.03. Note that to fully vent the pressure from Accumulator 236.15 a vent valve on the safety valve must be manually opened. Shutoff Valve 104.03 may be closed to isolate the Pilot Pressure Stand from the P1 Pressure Header Line. The Pilot Pressure Stand supplies pilot pressure fluid to the various directional control valves in the Coiler section of the Hot Mill which require a source of external pilot pressure fluid.

An accumulator stand which includes Piston Accumulator 245 is also connected to the P1 pressure Header Line. A DIN Cartridge Valve Assembly consisting of components 369, 370 and 388.01 is normally energized to allow pressurized hydraulic fluid to flow to and from the accumulator as needed by the demands of the Coiler hydraulic circuits. Note that before performing maintenance on the Coiler hydraulic system, even when the low pressure pumps are not operating, Shutoff Valve 094.03 must be manually opened to vent the stored energy in the accumulator.

The P1 Pressure Header Line supplies pressurized hydraulic fluid to Valve Stands 1, 2 and 3.

The High Pressure Pump Group and Pressure Header Line P2:

The high pressure pump group consists of nine pressure compensated piston pumps, 003.06 through 003.10 and 004.01 through 004.04, powered by Electric Motors 821.01 through 821.05 and 823.01 through 823.04, respectively. During operation of the Coiler, only eight pumps operate. The ninth pump is an installed standby.

The pumps draw freely from the reservoir through Butterfly Valves 072.06 through 072.10 and 073.01 through 073.04, respectively. The flow delivered by each pump flows through a pressure line filter (052.08 through 052.12 and 054.01 through 054.04, respectively). The filtered hydraulic fluid then flows through a check valve (157.48, 157.50, 157.52, 157.54 and 157.66, and 164.01 through 164.04, respectively) into a common pressure header line which supplies a manifold which includes Solenoid Vented Relief Valve 261.03. Though this relief valve may be vented to low pressure, in practice, this valve is always energized to high pressure, even when the low pressure pumps and motors are not operating. In addition, each pump is protected from overpressure by its own pressure relief valve (285.08 through 285.12 and 287.01 through 297.04, respectively). Any vented flow from Relief Valves 285.08 through 285.12 flows into a common return header line; backflow from that line to these relief valves is prevented by Check Valves 157.47, 157.49, 157.51, 157.53 and 157.55, respectively. The case drain flow from pumps 003.06 through 003.10 flows back to tank via a common return line. Backflow to the case drain port of these five pumps is prevented by Check Valves 143.13 through 143.17, respectively.

Also included on the manifold discussed above are two DIN Cartridge Valve Assemblies (363.01 + 364.01 + 388.02 and 363.02 + 364.02 + 363.03) which are plumbed in parallel with Flow Control Valves 168.01 and 168.02 and Check Valves 158.10 and 158.11. One set of valves controls the flow delivered to the P1 circuits on Coiler 1 and the other set of valves controls the flow delivered to the P1 circuits on Coiler 2. When the DIN Cartridge Valve Assemblies are energized pressurized hydraulic fluid may bypass unrestricted around the respective flow control valve.

The P2 Pressure Header Line supplies pressurized hydraulic fluid to Valve stand 4 and the Wrapper Roll circuits.