|

|

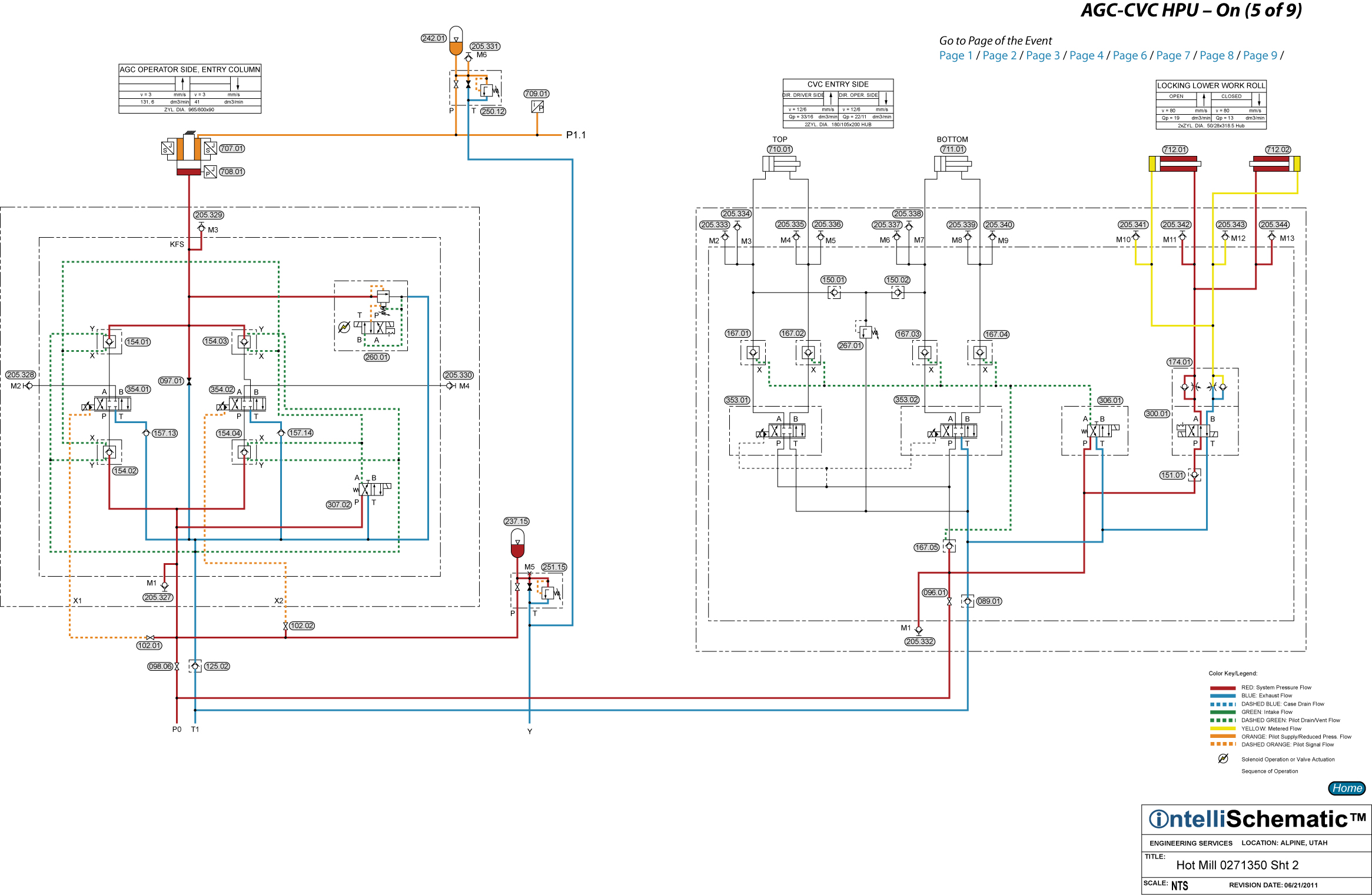

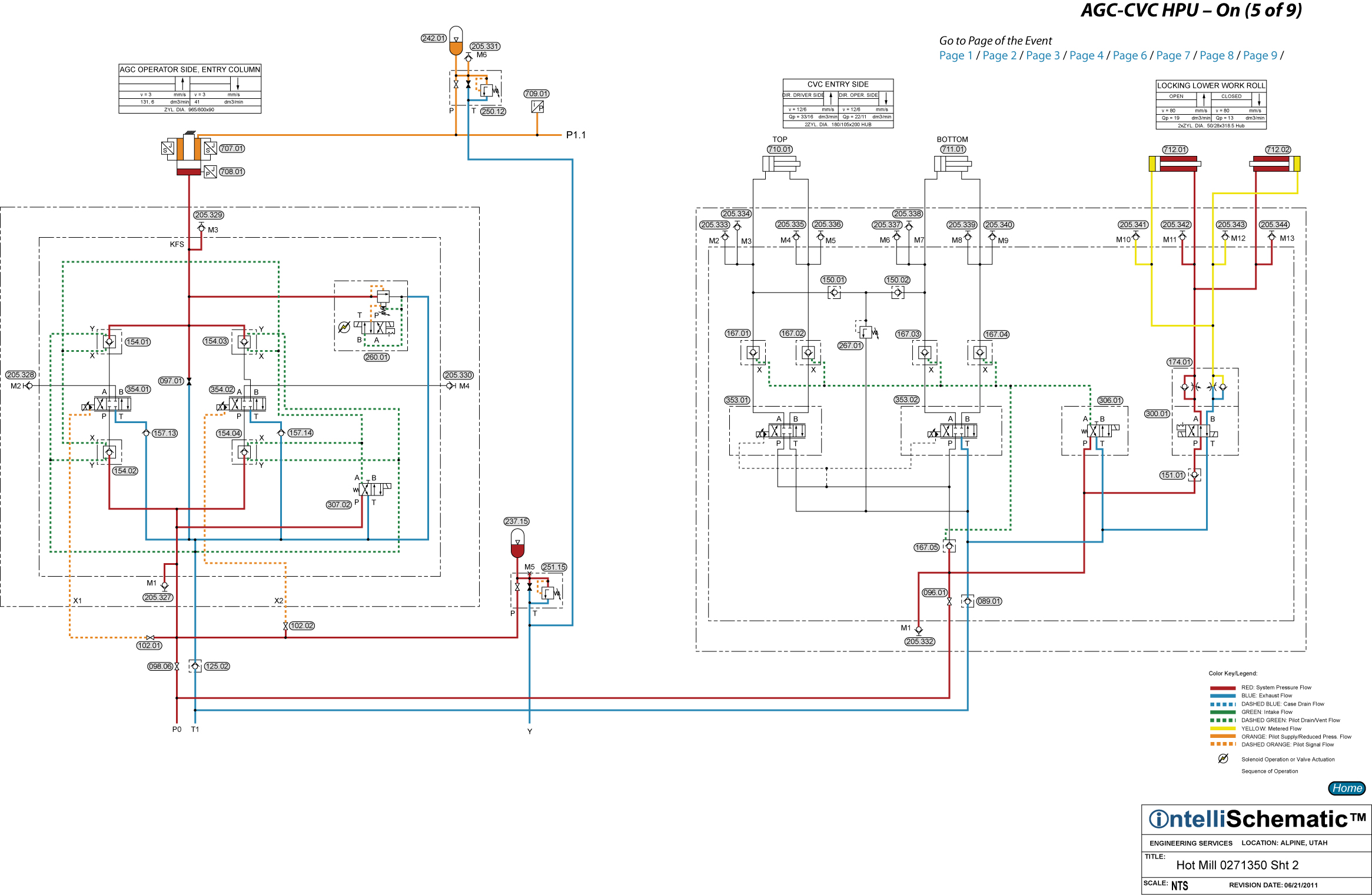

AGC-CVC HPU - On |

When the Operator turns the AGC-CVC hydraulic power unit (HPU) On:

1) Electric Motors 702.01 through 702.07 start, powering Pumps 011.02 through 011.08 which draw hydraulic fluid through opened shutoff valve 081.01 from the reservoir. The shutoff valve is equipped with a limit switch to ensure the motors cannot be started unless the valve is fully open. This pump group supplies supercharged fluid through Check Valve 127 to the inlet ports of Pressure Compensated Pumps 006.01 through 006.07, one of which is an installed standby pump. The pressure compensated pumps can operate for a short period of time without supercharged flow from Pumps 011.02 through 011.08 by drawing fluid from the reservoir through Check Valve 128, but only for a very short period of time! Excess flow from the supercharge circuit flows through Check Valve 123, which is equipped with a bypass spring to provide a small degree of backpressure to ensure positive pressure in the supercharge circuit. After the excess fluid flows through Check valve 123, the fluid then flows through Heat Exchanger 026 then back to tank. Each supercharge pump may be isolated from the supercharge circuit by closing a shutoff valve (078.09 through 078.15) in its inlet line. Each of the shutoff valves is equipped with a limit switch to prevent startup of the appropriate electric motor unless the shutoff valve is fully open.

2) When the temperature of the excess fluid reaches a predetermined temperature, Water Valve 031.02 is energized open providing flow of cooling water to the heat exchanger.

3) Electric Motors 701.01 through 701.07 start, powering Pressure Compensated Pumps 006.01 through 006.07. Each pump delivers flow though a pressure line filter (051.01 through 051.07, respectively) and a check valve (152.01 through 152.07, respectively) before delivering their flow into Pressure header Line P0. Each pump is protected by a pressure relief valve (273.01 through 273.07, respectively) which is isolated from a common return header line by a check valve (157.05 through 157.11, respectively). Each pump may be isolated from the supercharge circuit by closing a shutoff valve (071.02 through 071.08) in its inlet line. Each of the shutoff valves is equipped with a limit switch to prevent startup of the appropriate electric motor unless the shutoff valve is fully open.

4) Each of the pressure compensated pumps may be operated at low pressure or high pressure – the default is to operate at high pressure by leaving Directional Control Valve 303.xx de-energized.

5) The pressure compensated pumps deliver fluid to two accumulator stands, the AGC Accumulator Stand, which supplies reduced pressure fluid to the rod ends of the AGC cylinders, and the Bending-Balancing Accumulator Stand which supplies reduced pressure fluid to the rod ends of the Bending-Balancing cylinders.

6) In addition, the pressure compensated pumps deliver pressurized hydraulic fluid to all of the valve stands for the AGC-CVC circuits, as well as the five Looper circuits.