|

|

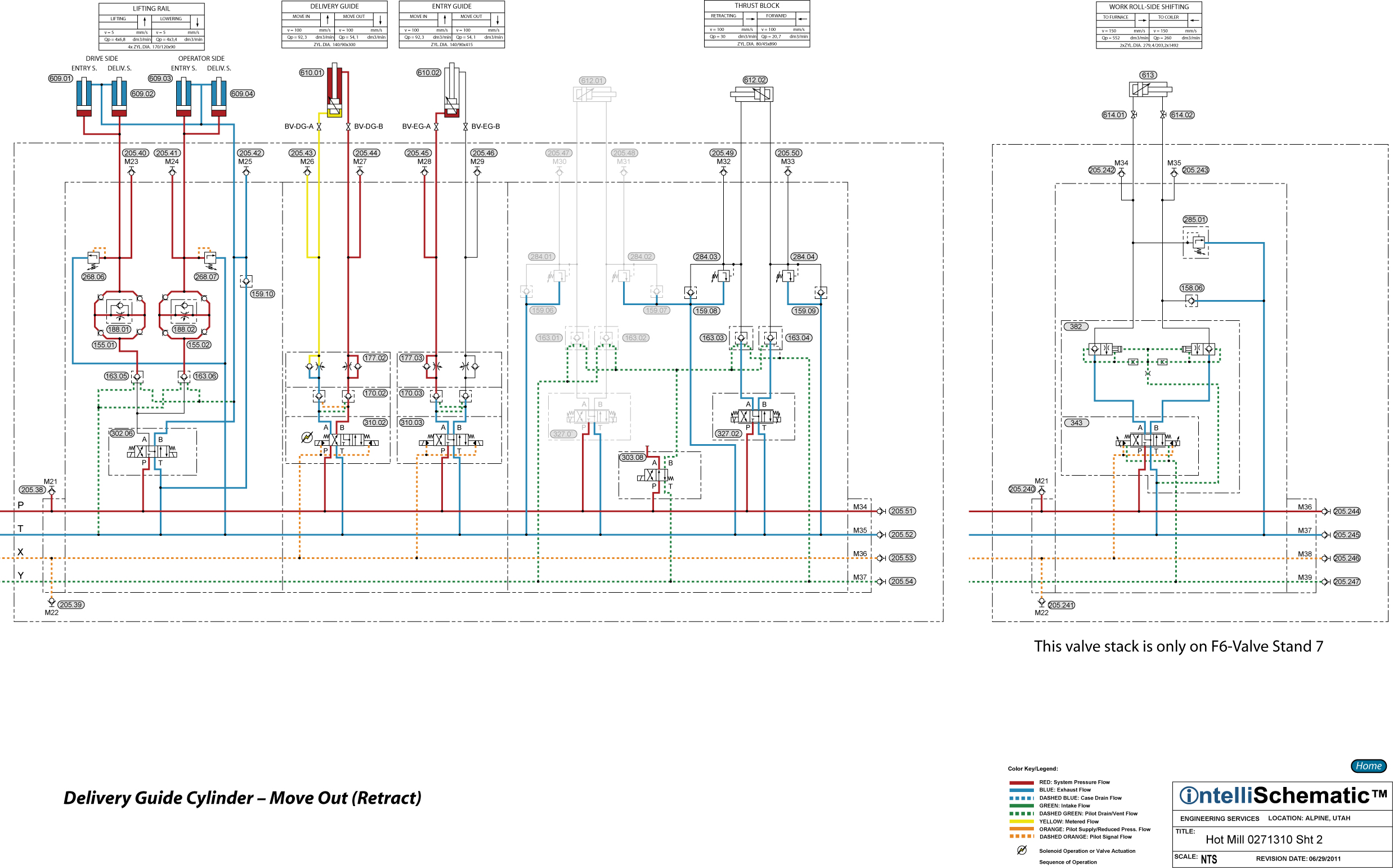

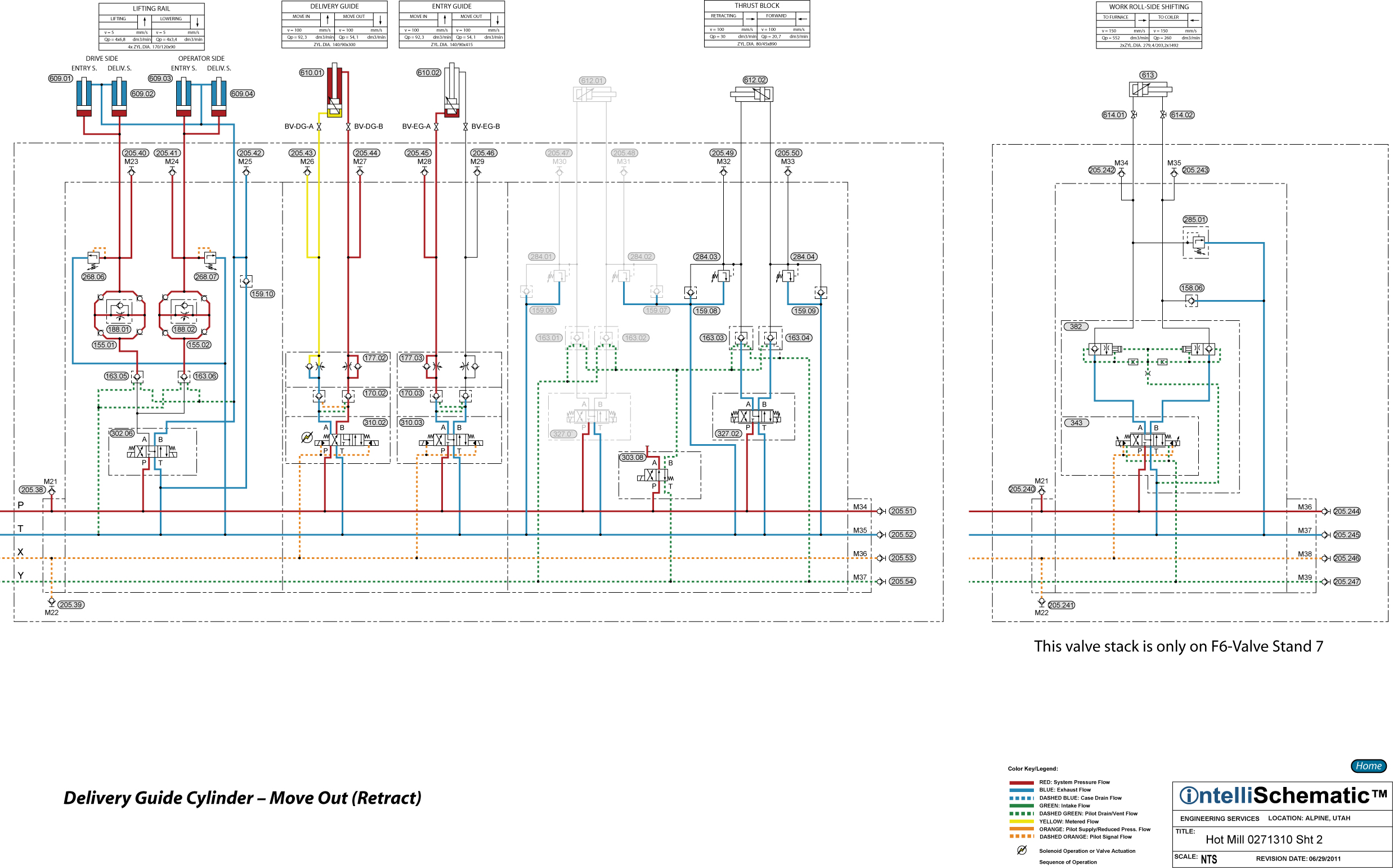

Delivery Guide Cylinder - Move Out (Retract) |

For previous sequences in this event see the event “Roll Change HPU – On.”

Note that this event describes the sequences for Mill Stand F1. The same sequences apply for stand F2 through F6, though the component numbers will change. In addition, these sequences also apply for the Entry Guide Cylinder. Refer to the relevant schematic for each stand for the appropriate component number.

1) Directional Control Valve 310.02 is energized to the crossover flow pattern allowing pressurized hydraulic fluid to flow through the valve, passing from P to B. Next, the fluid flows freely through the B-port check valve of Dual Pilot Operated Check Valve Module 170.02 and the B-port check valve of Dual Flow Control Valve Module 177.02 and into the rod end of Delivery Guide Cylinder 610.01 causing the cylinder to retract.

2) Exhaust fluid from the cap end of the cylinder is forced by the A-port check valve of the flow control module to flow through the A-port needle valve of the module, thereby achieving meter-out speed control of the retraction speed of the cylinder.

3) Next, the exhaust fluid flows through the A-port check valve of the pilot operated check valve module, which has been piloted open by pilot pressure from the B-side of the circuit.

4) Finally, the exhaust fluid flows through the directional control valve, passing from A to T, then back to tank through Check Valve 122.07 and Duplex Return Line Filter 045.01.