|

|

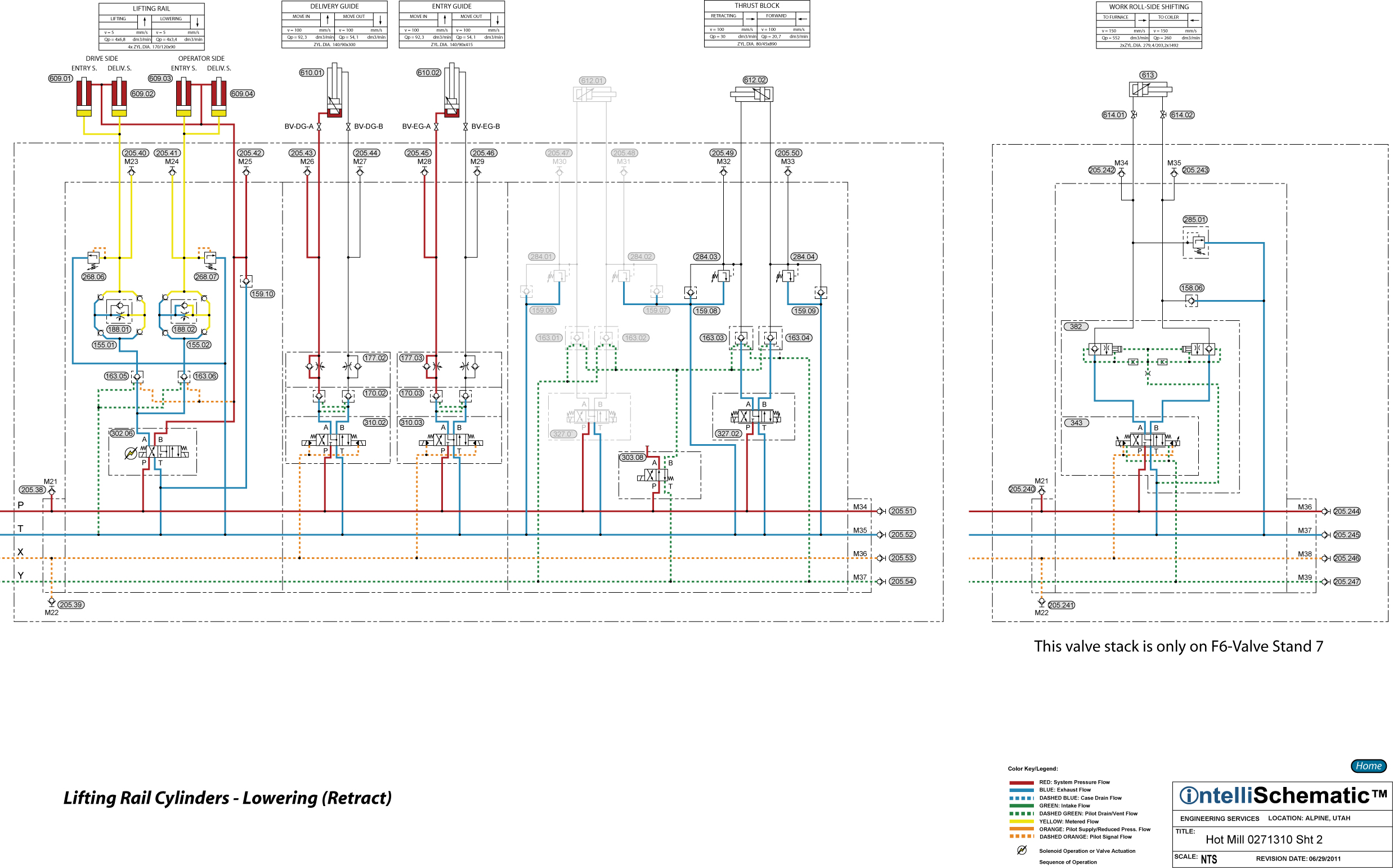

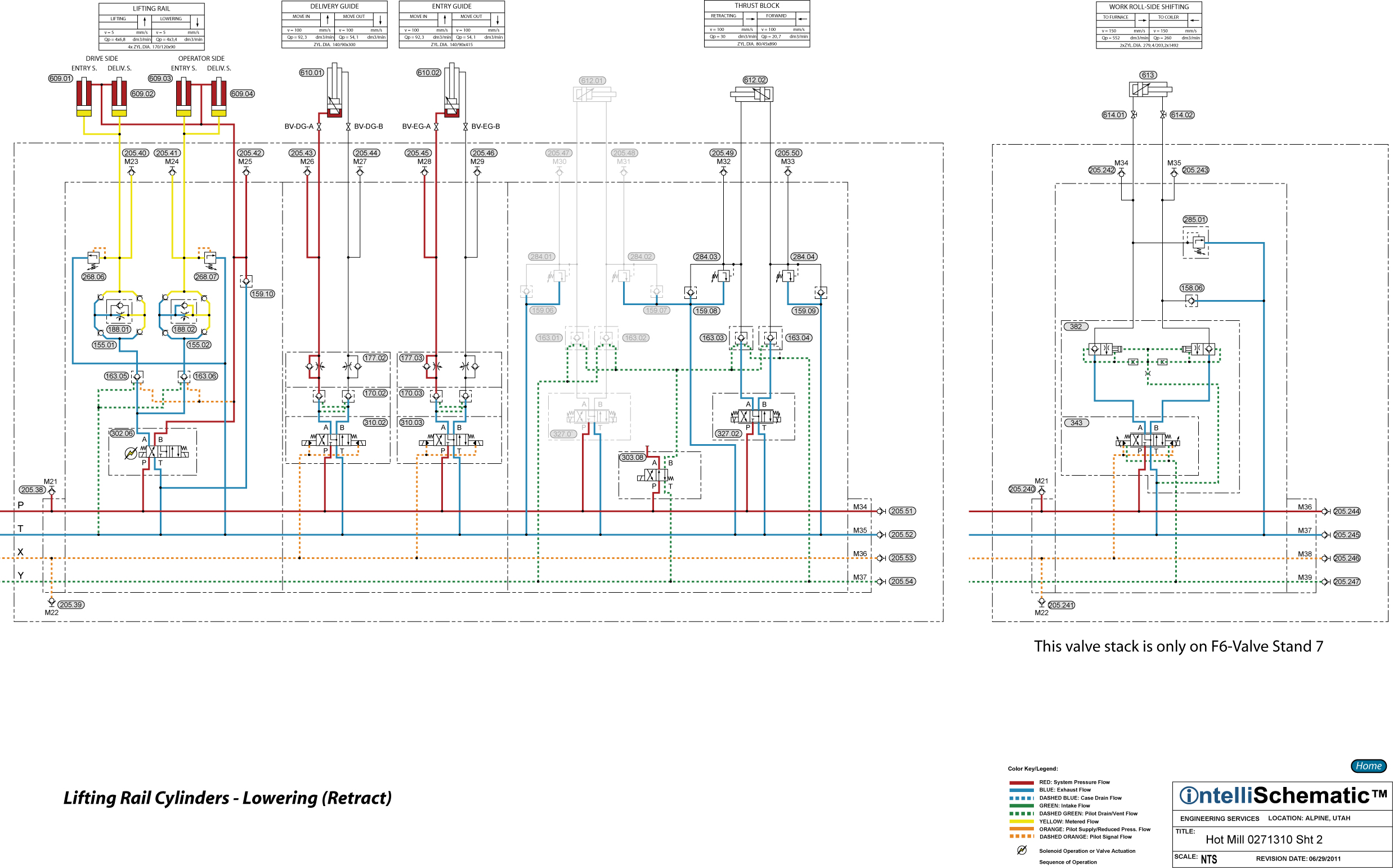

Lifting Rail Cylinders - Lowering (Retract) |

For previous sequences in this event see the event “Roll Change HPU – On.”

Note that this event describes the sequences for Mill Stand F1. The same sequences apply for stand F2 through F6, though the component numbers will change. Refer to the relevant schematic for each stand for the appropriate component number.

1) Directional Control Valve 302.06 is energized to the crossover flow pattern allowing pressurized hydraulic fluid to flow through the valve, passing from P to B. The fluid then flows into the rod ends of Lifting Rail Cylinders 609.01, 609. 02, 609.03 and 609.04, causing the cylinders to retract.

2) Exhaust flow from cylinders 609.01 and 609.02 flows through Rectifier Plate 155.01 and Pressure Compensated Flow Control Valve 188.01. Flow through these valves is as follows: Using compass points, the incoming fluid is blocked by the NW check valve. The fluid flows through the NE check valve, then toward the flow control valve, as the fluid is blocked by the SE check valve. The check valve which is part of the flow control valve forces the fluid to flow through the flow control from right to left (in the symbol) thereby achieving meter-out flow control of the retraction speed of the two cylinders. After flowing through the flow control valve, the fluid exits the rectifier plate by flowing through the SW check valve. The rectifier plate ensures the hydraulic fluid always flows through the flow control valve in the same direction regardless of whether the fluid is flowing to or from the cylinders. In this way, the extension and retractions speeds will always be identical.

3) The exhaust flow from cylinders 609.03 and 609.04 flow through Rectifier Plate 155.02 and Pressure Compensate Flow Control Valve 188.02 in a similar flow route.

4) The exhaust fluid then flows freely through Pilot Operated Check Valves 163.05 and 163.06 which have been piloted open to allow reverse flow by pilot pressure from the B-side of the circuit.

5) Finally, the exhaust fluid flows back to tank through the directional control valve, passing from A to T, then through Check Valve 122.01 and Duplex Return Line Filter 045.01.

6) Note that Pressure Relief Valves 268.06 and 268.07 protect the cap ends of the cylinders from overpressure caused by external load forces while Check Valve 159.10 provides makeup fluid to protect the rod ends of the cylinders from cavitation during such an occurrence.