|

|

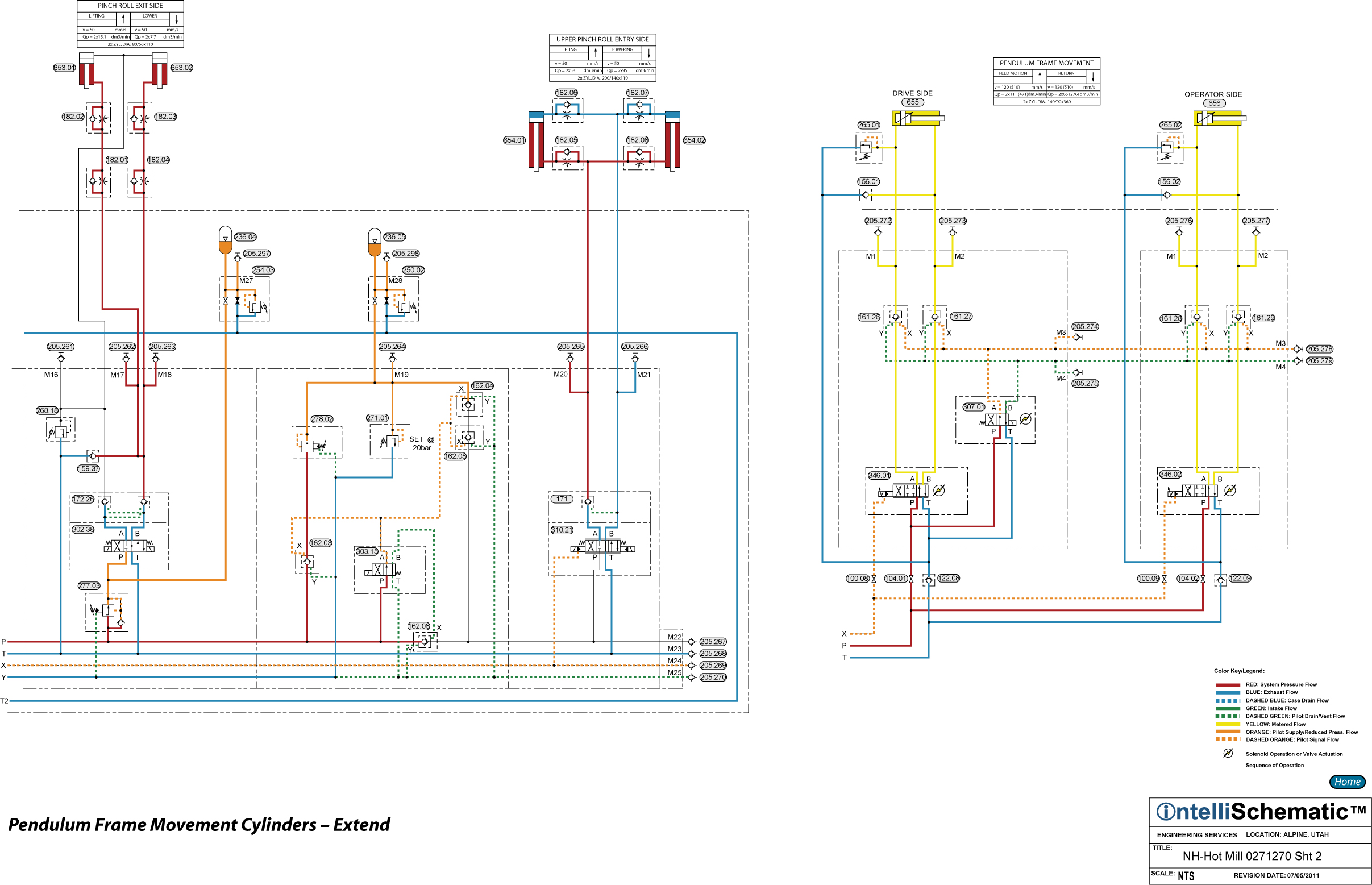

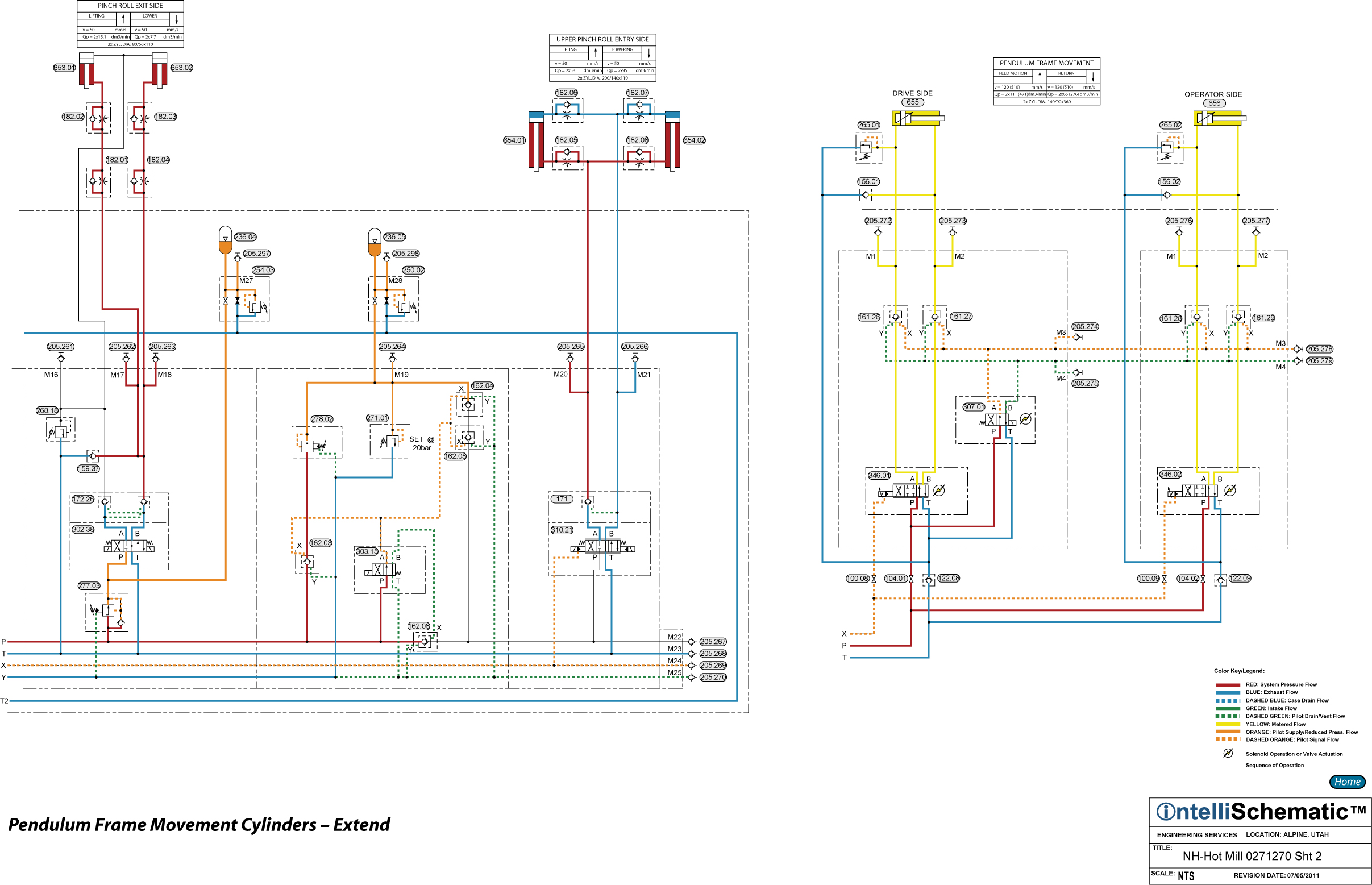

Pendulum Frame Movement Cylinders - Extend |

For previous sequences in this event see the event “Roll Change HPU – On.”

1) Directional Control Valve 307.01 is energized to the parallel flow pattern allowing pressurized hydraulic fluid to flow through the valve, passing from P to A, delivering pilot pressure to pilot open Pilot Operated Check Valves 161.26, 161.27, 161.28 and 161.29.

2) Proportional Directional Control Valves 346.01 and 346.02 are energized to the parallel flow patterns, allowing pressurized hydraulic fluid to pass through the valves from P to A. Next, the fluid flows freely through Pilot Operated Check Valves 161.26 and 162.28 (respectively) into the cap ends of Drive Side Pendulum Frame Cylinder 655 and Operator Side Pendulum Frame Cylinder 656 (respectively) causing the cylinders to extend. The proportional directional control valves control the extension speed of the cylinders using both meter-in and meter-out flow control.

3) Exhaust fluid from the rod ends of the cylinders flows through Pilot Operated Check Valves 162.27 and 162.29 (respectively) which were piloted open in step 1, above. Then the exhaust fluid flows back to tank after flowing through the proportional directional control valves, passing from B to T, then through Check Valves 122.08 and 122..09 (respectively) and Duplex Return Line Filter 045.01.

4) Note that if an external load force acts to retract either of the two cylinders, Pressure Relief Valves 265.01 and 265.02 (respectively) will vent overpressure fluid to tank, protecting the cylinders from overpressure, and Check Valves 156.01 and 156.02 (respectively) will allow makeup fluid to flow into the rod ends of the cylinders to protect the rod ends against cavitation.