|

|

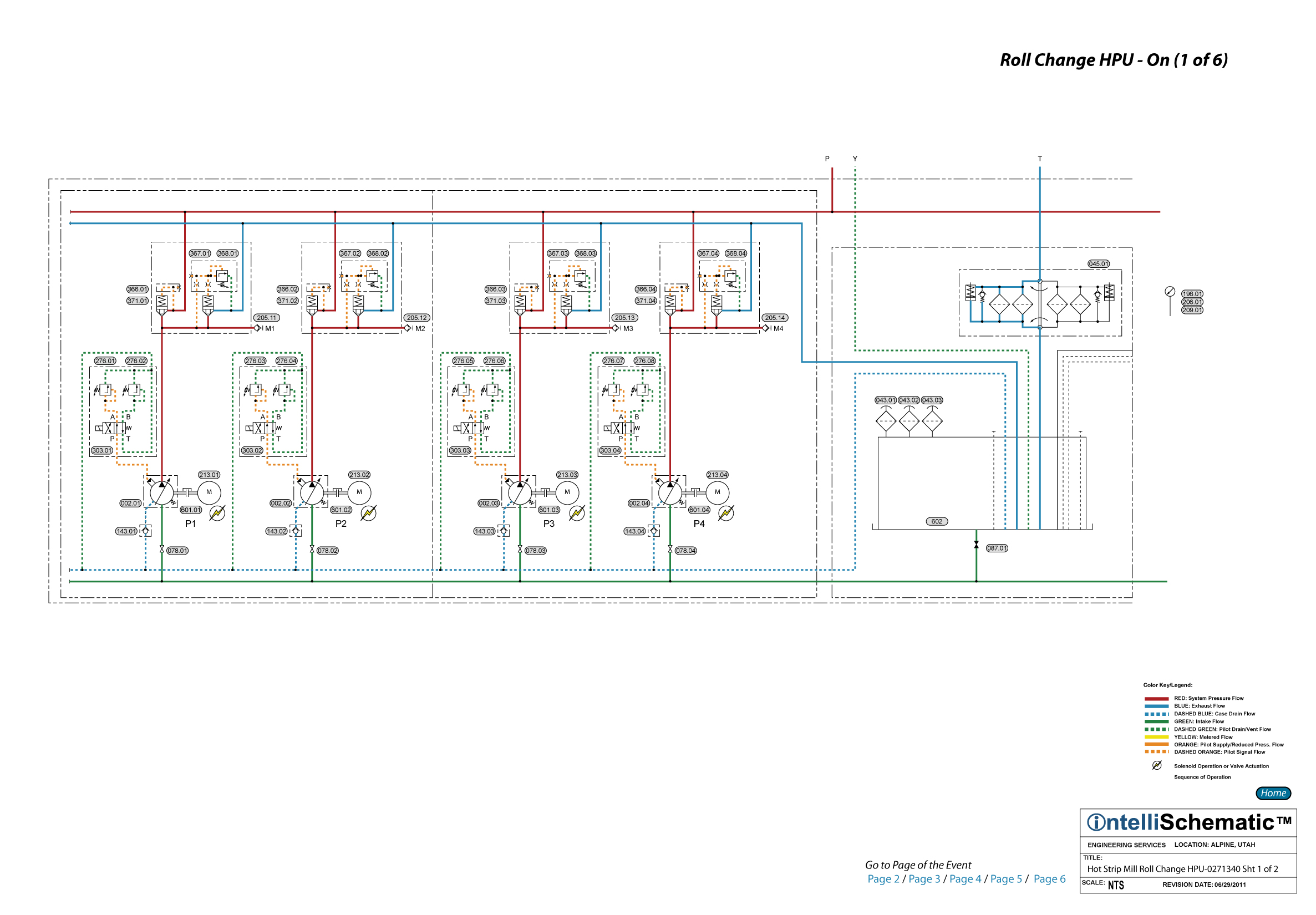

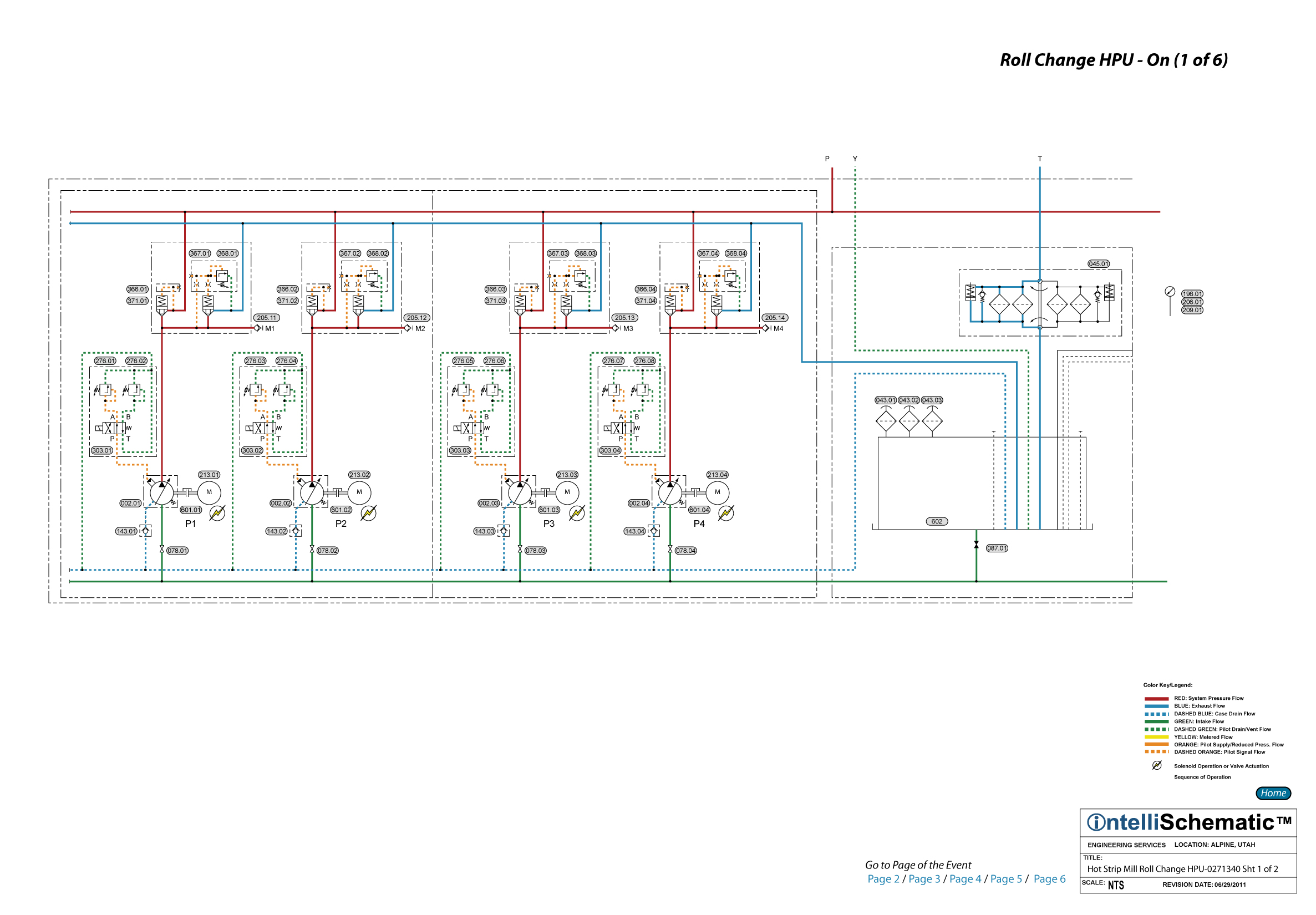

Roll Change HPU - On |

When the Operator starts the Roll Change hydraulic system, Electric Motors 601.01 through 601.07 start, powering Pressure Compensated Pumps 002.01 through 002.07. Note that normally only six of these units run with one unit being an installed standby unit.

1) The inlet port of each pump may be isolated from the reservoir by an inlet shutoff valve (078.01 through 078.07, respectively) installed in its inlet line. In order to prevent cavitation of the pumps, each shutoff valve is equipped with a limit switch which is wired to prevent startup of the electric motor unless the valve is fully open.

2) The setting of the pressure compensator on each pump may be set at either of two pressure values by using a solenoid-operated directional control valve (303.01 through 303.07, respectively) to switch between a pair of pressure relief valves (276.01 through 276.14, respectively), although current practice at the mill at the time of this writing is to always operate at high pressure.

3) Fluid delivered by the pump flows into Main Pressure Header Line P after flowing through a DIN Cartridge Check Valve Assembly (366.01/371.01 through 366.07/371.07, respectively). A DIN Cartridge-type Proportional Pressure Relief Valve Assembly (367.01/368.01 through 367.07/368.07, respectively) protects each pump from overpressure.

4) The case drain line fluid of each pump flows through a check valve (143.01 through 143.07, respectively) into a common return line back to tank.

5) Main Pressure Header Line P provides pressurized hydraulic fluid to the seven valve stands in the Roll Change hydraulic system as well as providing fluid to a pilot pressure circuit.

6) The pressurized hydraulic fluid supplied to the pilot pressure circuit flows through Pressure Filters 052.01 and 052.02. Shutoff Valves 094.01 and 094.02 may be opened or closed to select which filter the pilot pressure fluid will flow through, allowing each of the filters to be serviced while the hydraulic system is operating. Outlet Check Valves 157.01 and 157.02 prevent pressurized fluid from flowing back into the filter housings. Pressure Reducing Valve 278.01 reduces the pressure of the pilot pressure fluid. Accumulator 236.01 compensates for any lag time of the pressure compensators on the pumps by providing a reserve volume of pilot pressure fluid.