|

|

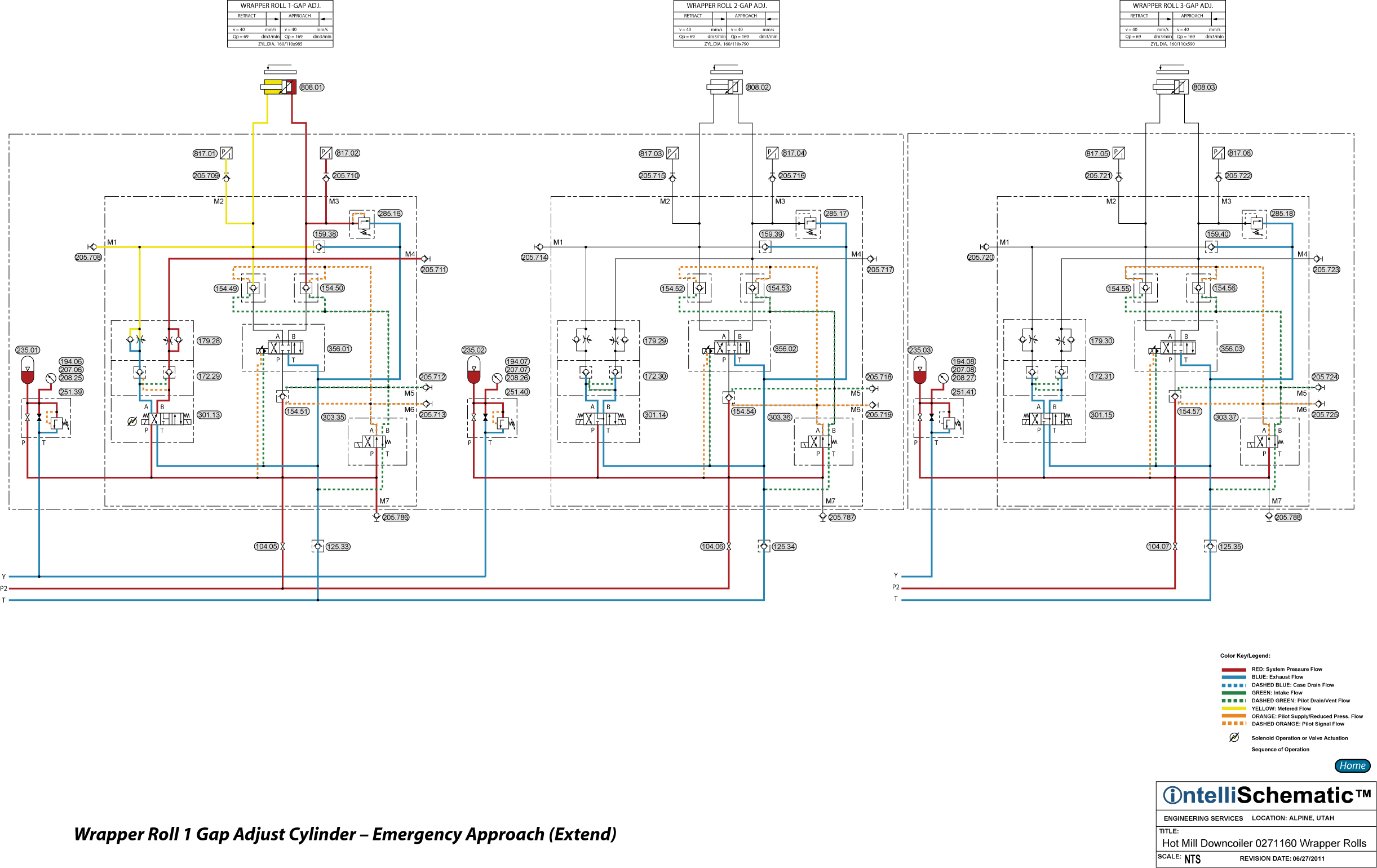

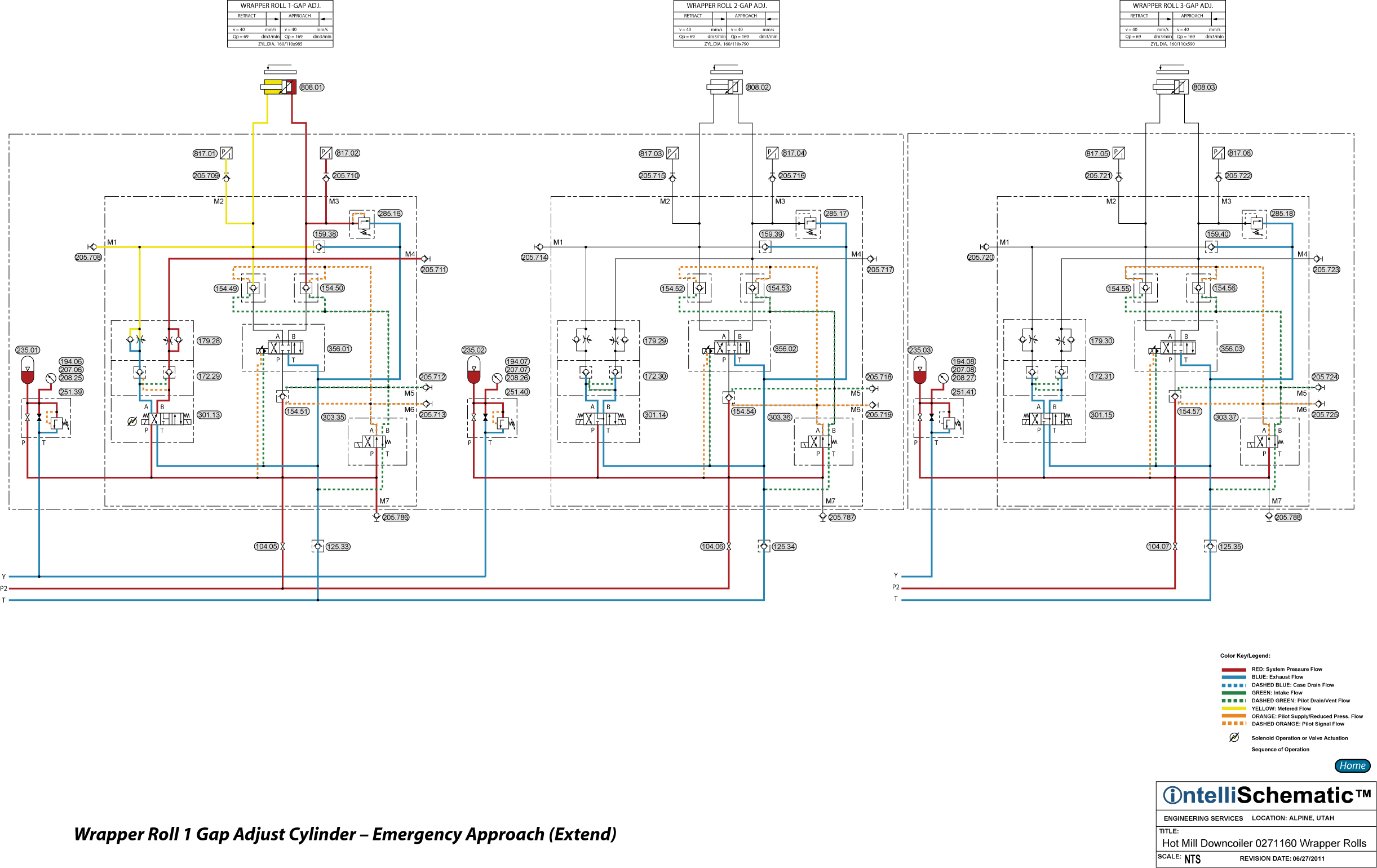

Wrapper Roll 1 Gap Adjust Cylinder - Emergency Approach (Extend) |

For previous steps in this sequence see the event “HPU – On.”

This circuit allows the position of this cylinder to be controlled in the event of a problem with the servo valve circuit.

1) Directional Control Valve 301.13 is energized to the crossover flow pattern allowing pressurized hydraulic fluid to pass through the valve from P to B. Next, the fluid flows freely through the B-port check valve of Pilot Operated Check Valve Module 179.29 and the B-port check valve of Flow Control Valve Module 179.28 then into the cap end of Wrapper Roll 1 Gap Adjustment Cylinder 808.01, causing the cylinder to extend.

2) Exhaust fluid from the rod end of the cylinder is forced to flow through the A-port needle valve by the A-port check valve of the flow control module, thereby achieving meter-out speed control of the extension speed of the cylinder.

3) Next, the exhaust fluid flows freely through the A-port check valve, which has been piloted open by pilot pressure from the B-side of the circuit, of the pilot operated check valve module. Finally, the exhaust fluid flows back to tank passing from A to T through the directional control valve, then through Check Valve 125.33 and Duplex Return Line Filter 045.03.

4) Note that Pressure Relief Valve 285.16 protects the cap end of the cylinder from overpressure caused by load forces and Check Valve 159.38 provides make-up fluid to prevent cavitation at the rod end of the cylinder during the forced retraction of the cylinder.