|

|

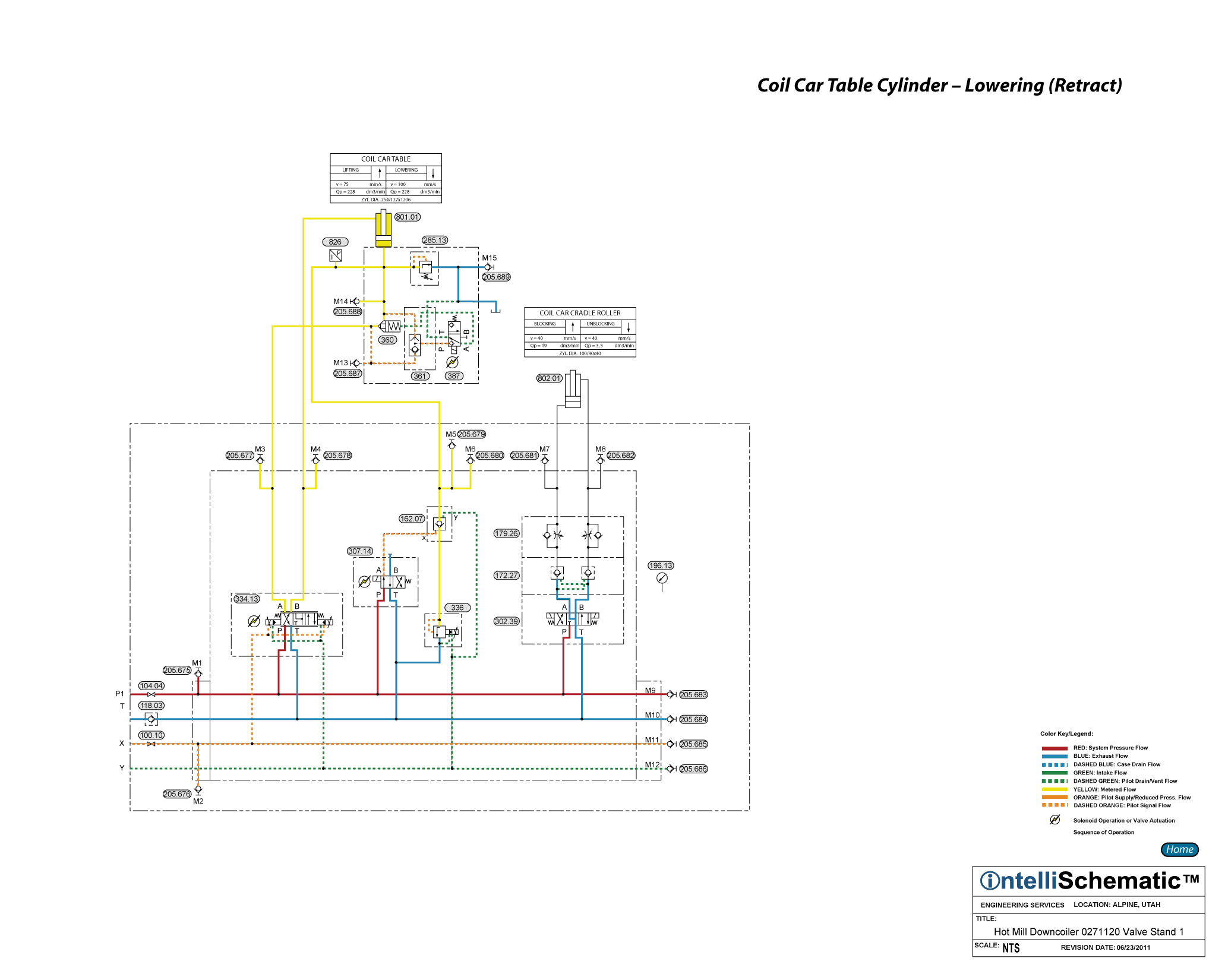

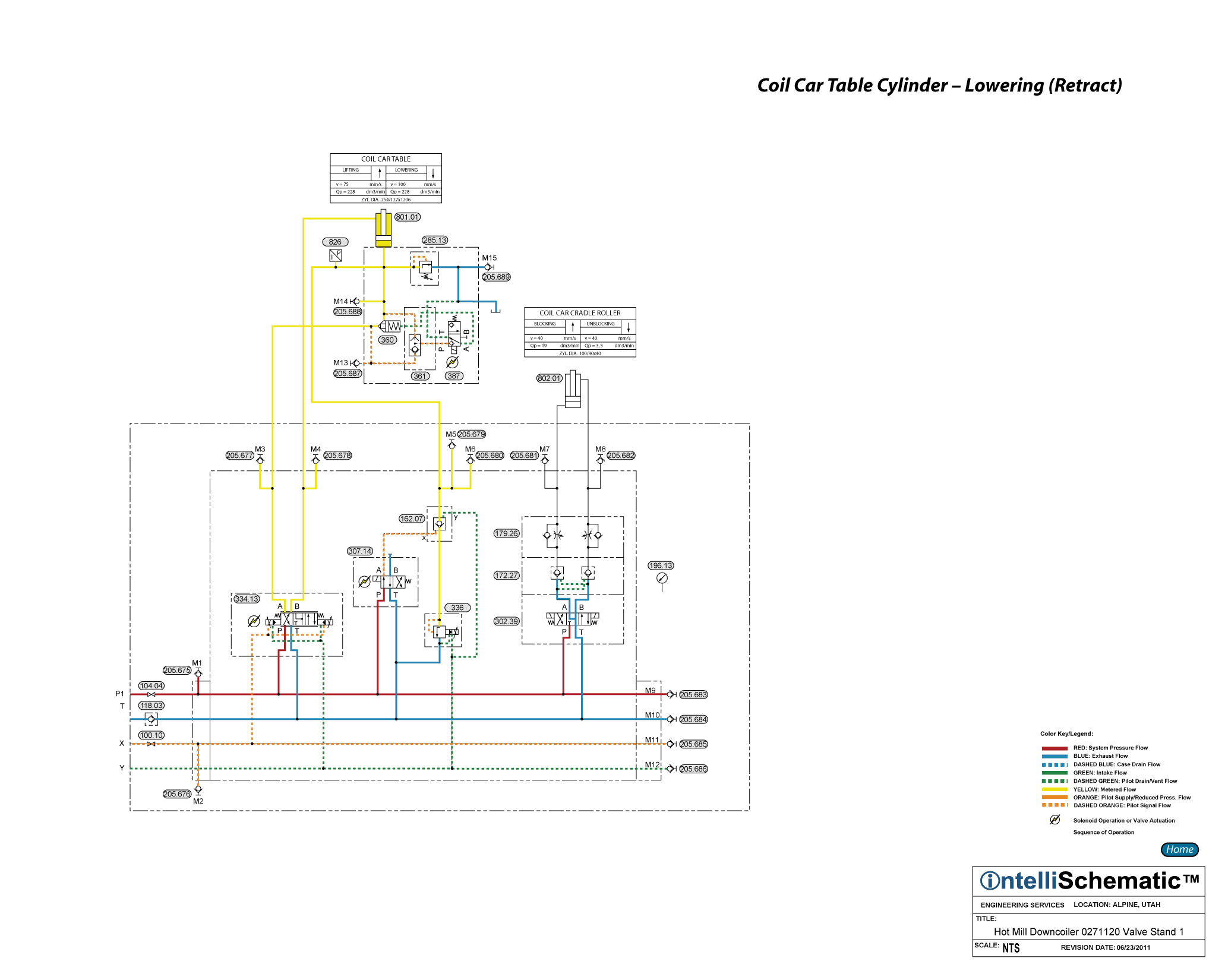

Coil Car Table Cylinder - Lowering (Retract) |

For previous steps in this sequence see the event “HPU – On.”

1) Before Coil Car Table Cylinder 801 is lowered, Directional Control Valve 307.14 is energized to the parallel flow pattern providing pilot pressure to open Pilot Operated Check Valve 162.07, connecting Proportional Pressure Relief Valve 336 to the cap end of the cylinder. The pressure setting of the relief valve is adjusted based on the weight of the coil.

2) Proportional Directional Control Valve 334.13 is energized to the crossover flow pattern.

3) Simultaneously, Directional Control Valve 387 is energized, venting the spring chamber of DIN Cartridge Insert Valve 360 allowing the DIN valve to open allowing flow through the DIN valve in either direction.

4) Pressurized hydraulic fluid flows through the proportional directional control valve passing from P to B then into the rod end of the cylinder causing the cylinder to retract.

5) Exhaust fluid from the cap end of the cylinder flows through the DIN valve passing from side to nose, then through the proportional directional control valve passing from A to T. Finally, the exhaust fluid flows back to tank through Duplex Return Line Filter 045.03.

6) The cylinder travel speed as well as the starting and stopping velocity ramps are controlled by inputs to the electronic control card for the proportional directional control valve. Pressure Relief Valve 285.13 protects the cylinder from overpressure caused by overloading. This relief valve protects the cylinder even when the DIN valve assembly is closed (de-energized).